| s/y Fiona - our Bruce Roberts Offshore 44' |

| |  | |  | |  | |

Copyright (c) 2005-2023 Martin Erlandson, Sweden

Achievements of 2012, January-April

The electrical system got some many more workhours and also the battery compartment got painted.

Power distribution got easier and with a nice & tide look.

Left is the wounderful DEKA start battery and a temporary 70Ah "battery bank" connected. Room for three 225Ah batteries but I will start with one for now.

The onboard computer is up and running nicely. Here connected to the HF Radio and receaving some weather fax images.

Ok, it's winter again. But this thime we checked out the Dolomiti area, Cortina, Sella Ronda and some more wounderful places. Perfect weather the whole time!

Co-welder #2 in position...

Grey watertank got smaller then planned, about 40 liters instead of 100 due to storage space went up in priority after all. Placed left of mast and under the hotwater tank under the sofa in saloon. Welding station to the left. Old Smashweld 250 under the table and a Kemppi Tig on top. Acetylen gas stuff is also in place. The blue in the middle is the coffy cup ;-)

Here is the 40 liter hotwater tank in place on top of the grey water tank. This is the settee in the salong and in the back rest is a heating konvektor. A "intelligent" fan will push air up the neck...

I constructed a isolation transformer (220V to 220V) on 2200W with overheating protection (80 degrees), overcurrent protection (fuse 10A) with a home-made soft start circuit. In the case there is also a commercial 1-phase energy meter with memory for the latest 24 Hour and the latest 31 days and a total W counter. So I can see how much power I consume when moored.

It can internally be rewired internally to a 110V to 220V operation. Could use a switch but that's not done yet.

The 220V selector on switch selects where to get the 220V from, either from the inverter on-board or from transformer. The 220V hot-water heater, 220V heater and 220V battery charger is connected before the selector switch i.e. they can only work on shore power.

I had an idea on using the hot-water heater as a dump-load when batteries are fully charged - but there is still some unsecure thoughts about it.

I considered the possibility to use 3-phase but that would increase the size and weight of the transformer. Also the 220V 16A (3500W) was too much and shore power at this rate is very rare. Even the cables gets clumsy and handle unfriendly. I also noted that the boat is well isolated enough to sustain +18 degrees inside when it's around -5 to -10 degrees outside. Ventilation fans needs to be off and controlled amount of natural ventilation of course. All this with 2000W of heating from 220V shore power.

Left is the Watt/hour meter.

In parallel I can start the diesel heater witch will quickly raise the temperature inside. The Eberspächer heater starts on maximum power 9.5kW and heats up the water quite quickly to about 80 degrees and then goes down on power. On the lowest power level it's quite silent and consumes very little power, ca 1.5 kW.

9.5kW-125W, 7.5kW-80W, 3.2kW-48W, 1.5kW-36W.

One possible drawback is that the Amp and Volt meter is connected after the 220V selector switch so I can't see the current drawn by the 220V heaters nor charger. I do see the voltage drop when they are on.

Hot water heater is 700W, the 220V heater is 1000W or 2000W (Switch on thermostat) and the charger would be around 400W maximum.

Apparently I can't use all at the same time as the wattage would be to high for the transformer and it's fuse. The heating system is actually also heating the hot-water so there would not be a need to run these two together. The present battery charger will be replaced with an inverter with an internal battery charger and shore-power-overload-protection Mastervolt MassCombi 12/2000-100.

The inverter consumes <15W on idle ie powered but no load.

Yes the Heat is soon On!

Below is the Heave Duty Continious Blower!

The CV shaft broke - well not really - only the rubber stuff got a glitch and throw out very greeasy greas in the engine room. So out with it, cleaning, inspection new grease and sealings. Good as new. Just needs paint.

Some label in the electrical panel is in place. The upper square is for 220 V & A. Shore/Off/Onboard selector, fuse and switches for 220 outlets.

Switches populated with functionality.

I'll go for self adeshive labels as it's easy to change.

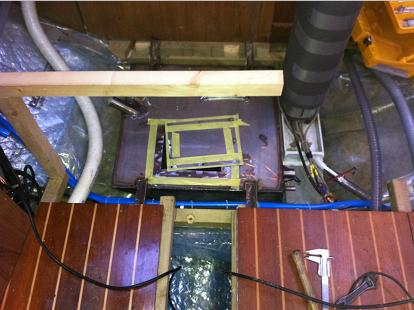

Water pumps below flooring, fresh and seawater. Valves for tank communication and future Watermaker.

22 mm copper tubes soldered onboard (acetylen) for the heating system. Cooling off on the stove. White coffy cup.

The old oven also got new "buttons" or valve handles(?) The oven is ok but can't get warmer in the oven then 220 degrees.

Of course a Force 10 with 4 flames is better in balence and probably any other way too.

At least it will eventually fit...