| s/y Fiona - our Bruce Roberts Offshore 44' |

| |  | |  | |  | |

Copyright (c) 2005-2023 Martin Erlandson, Sweden

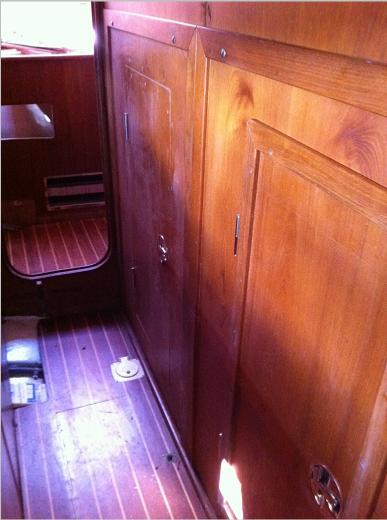

In the rear is one of the four large engine room panels. They where screwed on witch made it hard & slow to access the engine room. So I made four smaller doors in each panel. So I now have quick access and it's easy to shut off water intakes etc.

Sound or noise insulation rather, needs to be improved.

Fuel filter and injectionpump with throttle/stop easy to reach as with some water valves.

And the heater. No the blue box is not a coffy cup - it shouldn't be there at all.

Ventilation is now done. Here is the controller wich runs the fans Engineroom and Dryer if we have something that charges the batteries. Battery has here 13.5 volts and humidity in Dryer locker is 54%Rh witch is too dry to start the fan; 0%. The main ventilation fan runs at slow rpm or 21% of 13.5 volt - silent that is. If fully chargin > 14volt we run up to 80%.

Right is the finished flooring inside the dryer. The blue handle is to the heating konvektor so I can easely turn on off the heat. The grey valve is for dumping to sea or deck or off.

Time to fix the Head.

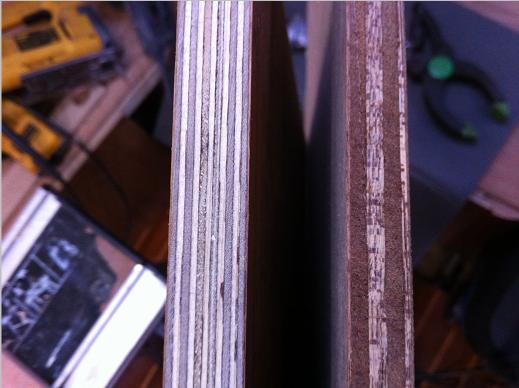

But look at the two different plywood sheets to the left. Both 1/2 inch 13mm. Advice: Try to get the type with more layers. Much stronger and easier to work with. No filler needed...

Head - not much to write about really. Lots of testing prototyping and then compromise. It should feel fresh to enter here!

Eventually the ice lost its grip :-)

Plastic flooring and walling...

Some hatches, shelfs, locks and the wachingmachine missing.

A drawer was made under the chart table as I need to put away lots of stuff all the time. Documetation gots its place and next to it will be a fire distinguisher.

The battery switches to the engine - heavy duty of course and above is the domestic auto fuse/switch at 80A. Mounted inset for protection.

Lowest to the floor is a heat konvektor with the air in and out lets.

Outdoors got the peek finally its teak planks, 25 mm thick and lots of bolts. Here two small pieces still is missing.

The peek wood made it well through the Pentland Firth where we met my worst waves ever - so far (July 2013)

Below is a glimt of the temporary sprayhood - here only one window. Instruments and SPEAKERS is working!

(Is that whisky in the glass?)

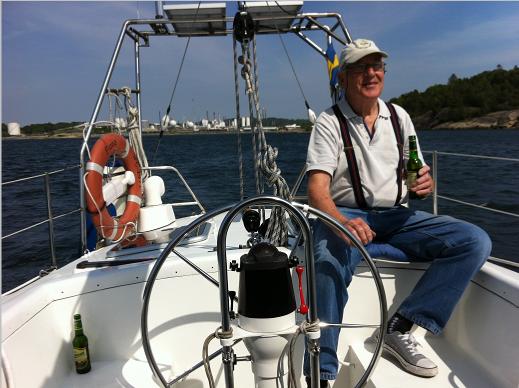

My hero and father at the rudder enjoying a beer motoring from the habour.

We met some friends and started to talk about someone who got a line stuck in the propshaft and had to go in the water...

My father just happend to mentioned that he had once had the same issue on a big cargo ship, up in the river of Congo, Africa in 1957 where they got a huge mooring chain in the propeller and had to cut it under water...

Same issue but a very different story!

Thanks Dad! :-)